T-ACNL-X2-80X340-FA-S-XN: A Comprehensive Guide to Understanding This Industrial Component

Table of Contents

If you’re working in the industrial, manufacturing, or engineering sector, you might have come across the term T-ACNL-X2-80X340-FA-S-XN. It might seem like a complex code at first, but this part plays a crucial role in various industrial applications. Whether you’re sourcing components for machinery or trying to understand the specifics of this part for a project, you’ve come to the right place. In this article, we’ll take a deep dive into everything you need to know about the T-ACNL-X2-80X340-FA-S-XN, from its specifications and applications to installation and maintenance tips.

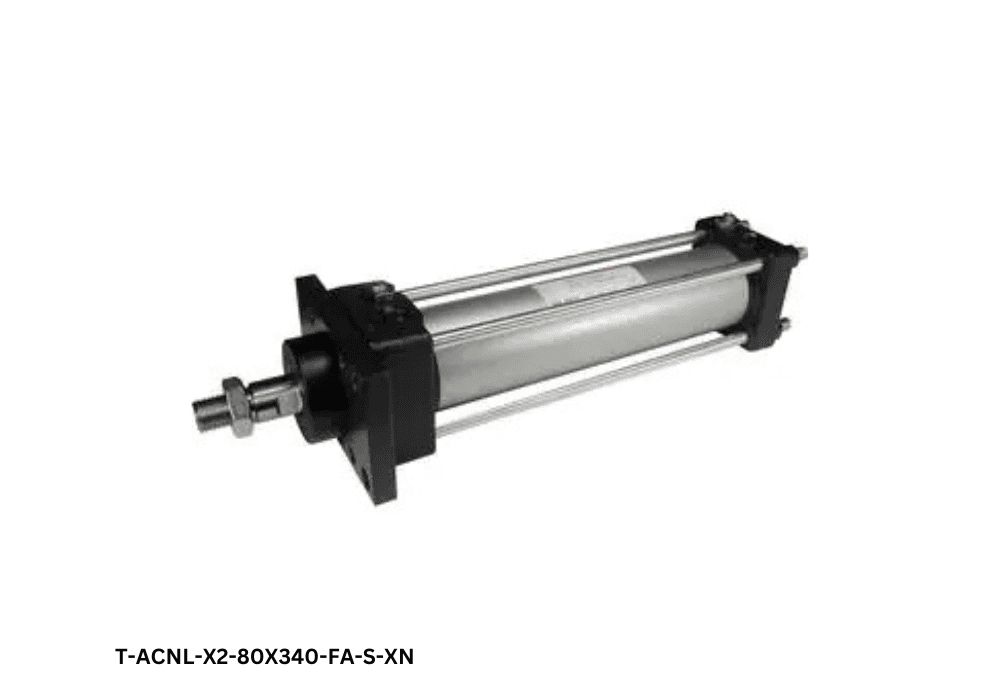

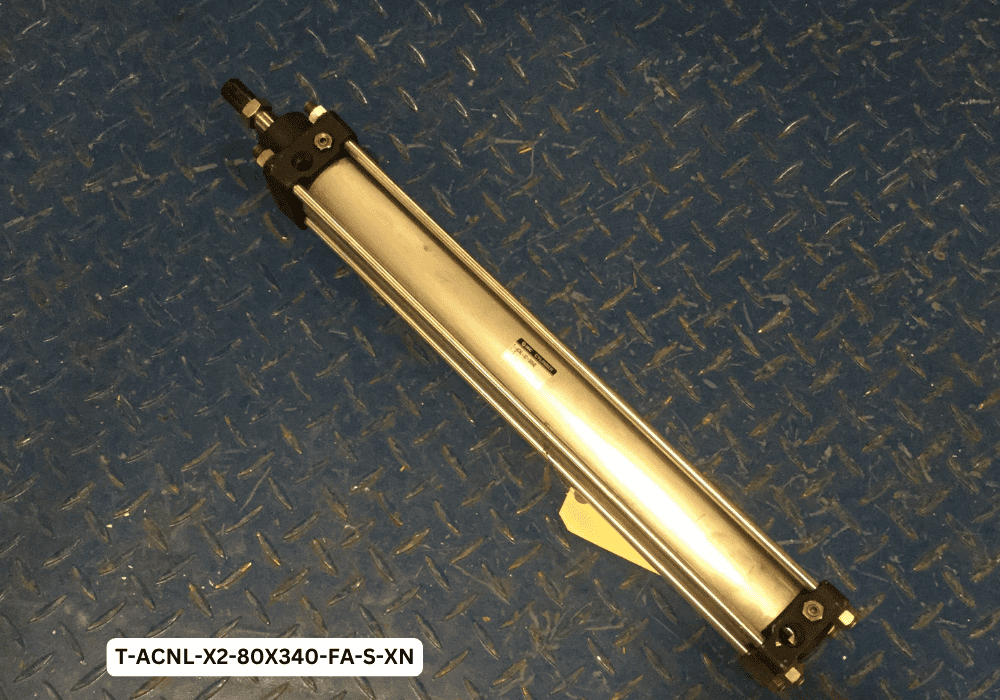

What is the T-ACNL-X2-80X340-FA-S-XN?

The T-ACNL-X2-80X340-FA-S-XN is an industrial component commonly used in various mechanical and automation systems. It is specifically designed to meet the rigorous demands of modern machinery, offering durability, precision, and reliability. Whether you are dealing with manufacturing equipment or automated systems, this part plays a crucial role in ensuring optimal performance.

But what exactly does this code mean? The alphanumeric code T-ACNL-X2-80X340-FA-S-XN describes various characteristics and specifications of the part. Breaking it down helps us understand what each segment stands for, indicating the type, size, configuration, and other technical details necessary for its specific applications.

Understanding the Components of the T-ACNL-X2-80X340-FA-S-XN

To fully grasp what the T-ACNL-X2-80X340-FA-S-XN represents, let’s break down its components:

- T-ACNL: This typically refers to the type and classification of the component. In this case, it may denote a specific kind of actuator or valve used in fluid systems.

- X2: Often indicates a variation or version of the part, showing it’s a second-generation model with specific improvements.

- 80X340: These numbers usually represent dimensions, such as length and diameter, crucial for fitting into the machinery it’s designed for.

- FA: Abbreviation for the specific function or configuration of the component (e.g., FA might stand for ‘Fluid Actuated’).

- S: This part may denote the material type, such as stainless steel, which is common for components that require high durability and resistance to corrosion.

- XN: This suffix often indicates a special feature or add-on, such as extra resistance to extreme temperatures or pressure.

By understanding this breakdown, you can determine whether the T-ACNL-X2-80X340-FA-S-XN fits your specific requirements and system setup.

Key Specifications and Technical Details

Knowing the technical details of the T-ACNL-X2-80X340-FA-S-XN is crucial for ensuring compatibility and efficiency in your applications. Below are some important specifications:

- Material: Typically, this part is made of high-grade stainless steel or another robust metal alloy, providing longevity and resistance to harsh environments.

- Dimensions: As indicated by the 80X340 section, the part measures 80mm in diameter and 340mm in length.

- Operating Pressure: This component is designed to handle pressure levels up to [insert PSI], making it suitable for high-intensity industrial uses.

- Temperature Range: Capable of operating in temperatures from -20°C to +150°C, the T-ACNL-X2-80X340-FA-S-XN is built for both low and high-temperature environments.

- Sealing Mechanism: Includes advanced sealing technology to prevent leaks and ensure maximum efficiency.

These details are essential when selecting the T-ACNL-X2-80X340-FA-S-XN for any project, ensuring that it meets the demands of your system.

Applications of the T-ACNL-X2-80X340-FA-S-XN in Industry

The T-ACNL-X2-80X340-FA-S-XN is versatile, finding use in a variety of industrial sectors:

- Automotive Manufacturing: In robotic assembly lines, it functions as an actuator, controlling the movement of parts and precision tools.

- Oil and Gas: Due to its durability and pressure resistance, it is used in drilling equipment and fluid control systems.

- Chemical Processing: The part’s ability to withstand corrosive materials makes it perfect for valves and control systems in chemical plants.

- Food and Beverage: Its stainless-steel construction is ideal for applications that require hygiene and resistance to corrosion, such as bottling or packaging machinery.

The T-ACNL-X2-80X340-FA-S-XN is designed to meet the diverse needs of these industries, ensuring reliable performance in challenging environments.

How to Choose the Right T-ACNL-X2-80X340-FA-S-XN for Your Needs

Selecting the right T-ACNL-X2-80X340-FA-S-XN component depends on several factors:

- Compatibility: Ensure the part matches the specifications and dimensions required by your system.

- Operating Environment: Consider the temperature and pressure conditions it will face; verify that the component’s limits align with these factors.

- Material Requirements: If you’re working in a corrosive or food-safe environment, stainless steel or other suitable materials are necessary.

Taking these considerations into account ensures you choose the most efficient and compatible T-ACNL-X2-80X340-FA-S-XN for your project.

Installation Guide for the T-ACNL-X2-80X340-FA-S-XN

Proper installation of the T-ACNL-X2-80X340-FA-S-XN is essential for optimal performance:

- Preparation: Ensure the area is clean, and you have all necessary tools, such as wrenches and sealing compounds.

- Inspection: Before installation, inspect the component for any damage or manufacturing defects.

- Mounting: Secure the part in its designated place, following the manufacturer’s instructions for torque specifications and alignment.

- Sealing: Apply the appropriate sealant to prevent leaks, especially in high-pressure systems.

- Testing: Once installed, test the system under controlled conditions to verify proper functionality.

By following these steps, you ensure that the T-ACNL-X2-80X340-FA-S-XN functions correctly and efficiently.

Maintenance and Care Tips for Optimal Performance

Maintaining the T-ACNL-X2-80X340-FA-S-XN prolongs its lifespan and ensures consistent performance:

- Regular Inspections: Check for signs of wear, corrosion, or damage regularly, especially in high-pressure or temperature environments.

- Lubrication: Apply the recommended lubricant to moving parts to reduce friction and wear.

- Replacement of Seals: Periodically replace seals to maintain pressure resistance and efficiency.

- Cleaning: Ensure that the part is kept free from debris or contaminants, particularly in industries where hygiene is crucial.

Consistent maintenance will keep your T-ACNL-X2-80X340-FA-S-XN running smoothly and prevent costly downtime.

Common Issues and Troubleshooting the T-ACNL-X2-80X340-FA-S-XN

While the T-ACNL-X2-80X340-FA-S-XN is built for durability, certain issues may arise:

- Pressure Leaks: Often caused by worn seals or incorrect installation. Inspect and replace seals as needed.

- Corrosion: In environments with harsh chemicals, even stainless steel can degrade.

- Temperature Fluctuations: Ensure that the operating temperature is within the component’s range; otherwise, performance may be compromised.

Addressing these issues promptly keeps the T-ACNL-X2-80X340-FA-S-XN functioning as intended.

Compatible Parts and Alternatives to the T-ACNL-X2-80X340-FA-S-XN

When looking for parts compatible with the T-ACNL-X2-80X340-FA-S-XN, consider:

- Seals and Gaskets: Ensure they match the specifications of the component for a proper fit.

- Alternative Components: Similar parts like the T-ACNL-X2-80X350-FA-S-XN may offer slightly different dimensions or features that suit specific needs.

By exploring compatible options, you can find the most suitable part for your system while ensuring efficiency.

Cost and Availability: Where to Purchase

The T-ACNL-X2-80X340-FA-S-XN is widely available from industrial suppliers and specialized retailers:

- Direct Purchase: Visit manufacturer websites or authorized distributors to ensure genuine parts.

- Online Marketplaces: Platforms like [insert relevant platforms] offer this part, but ensure you verify the seller’s authenticity.

Understanding the purchasing options available ensures you receive the best quality and price for the T-ACNL-X2-80X340-FA-S-XN.

T-ACNL-X2-80X340-FA-S-XN: How It Compares to Similar Components

Comparing the T-ACNL-X2-80X340-FA-S-XN to similar parts:

- Durability: This component excels in high-pressure environments compared to generic alternatives.

- Customization: With multiple versions available, the T-ACNL-X2-80X340-FA-S-XN offers more flexibility.

- Cost-Effectiveness: While slightly more expensive, its longevity makes it a cost-effective option in the long term.

Innovations and Future Trends Related to the T-ACNL-X2-80X340-FA-S-XN

Advances in materials and technology suggest that the future of the T-ACNL-X2-80X340-FA-S-XN will include:

- Smart Monitoring Systems: Integrating sensors for real-time performance data and predictive maintenance.

- Improved Materials: Exploring composite materials that offer greater resistance to temperature and pressure.

Safety Considerations When Handling the T-ACNL-X2-80X340-FA-S-XN

When dealing with the T-ACNL-X2-80X340-FA-S-XN, safety is paramount:

- Wear Protective Gear: Gloves and eye protection are essential during installation and maintenance.

- Follow Proper Procedures: Adhere to manufacturer guidelines for safe handling.

- Store Safely: Keep the part in a clean, dry environment to avoid damage before installation.

Case Studies: T-ACNL-X2-80X340-FA-S-XN in Real-World Applications

In industries like automotive manufacturing and chemical processing, the T-ACNL-X2-80X340-FA-S-XN has proven effective. For example:

- Automotive Sector: Used in precision robotic arms, enhancing production efficiency.

- Chemical Plants: Essential for controlling fluid flow, minimizing leaks, and improving safety.

How to Extend the Lifespan of Your T-ACNL-X2-80X340-FA-S-XN

To get the most out of your T-ACNL-X2-80X340-FA-S-XN:

- Routine Maintenance: Regular inspections and lubrication.

- Proper Storage: Store components in dry conditions to prevent premature corrosion.

- Use High-Quality Seals: Invest in reliable seals for maintaining pressure integrity.

Certifications and Standards Related to the T-ACNL-X2-80X340-FA-S-XN

This component adheres to industry standards such as [insert certifications], ensuring safety and quality compliance for various applications. When purchasing, verify these certifications to guarantee authenticity.

Feedback from Industry Professionals on the T-ACNL-X2-80X340-FA-S-XN

Professionals in the industry often commend the T-ACNL-X2-80X340-FA-S-XN for its reliability and performance, especially in challenging environments. Many prefer this model for its longevity and ease of maintenance.

Conclusion: Is the T-ACNL-X2-80X340-FA-S-XN Right for You?

The T-ACNL-X2-80X340-FA-S-XN is an ideal choice for those seeking a durable and versatile industrial component. Its compatibility with various systems and applications makes it a reliable solution for modern manufacturing and automation needs.

FAQs About the T-ACNL-X2-80X340-FA-S-XN

1. What does the code T-ACNL-X2-80X340-FA-S-XN mean?

It describes the part’s type, dimensions, function, and material specifics, helping identify its application.

2. Where can I buy the T-ACNL-X2-80X340-FA-S-XN?

You can purchase it through authorized distributors, manufacturer websites, and reputable online marketplaces.

3. Is the T-ACNL-X2-80X340-FA-S-XN suitable for high-pressure environments?

Yes, it is designed to withstand high pressure, making it ideal for demanding industrial applications.

4. How do I maintain the T-ACNL-X2-80X340-FA-S-XN?

Regular inspections, lubrication, and replacing seals are key steps for maintaining optimal performance.

5. Are there alternatives to the T-ACNL-X2-80X340-FA-S-XN?

Yes, similar components like the T-ACNL-X2-80X350-FA-S-XN may offer different specifications for specific needs.